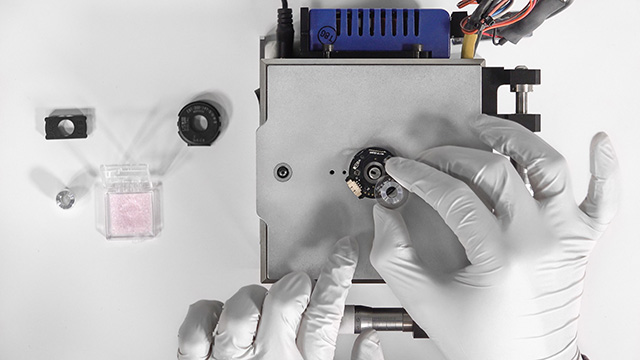

E8P OEM OPTICAL KIT ENCODER

E8P Features

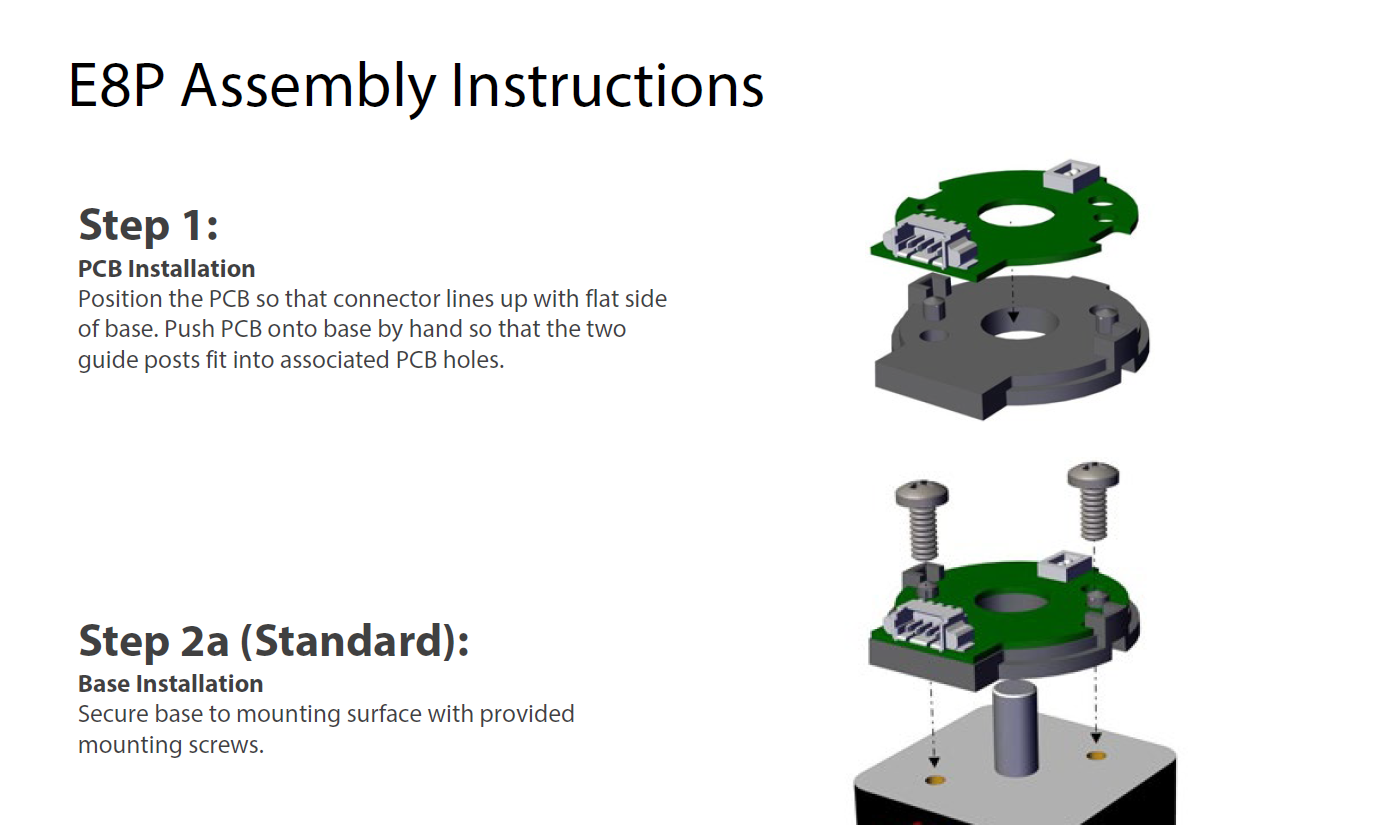

- Subminiature size, easy installation

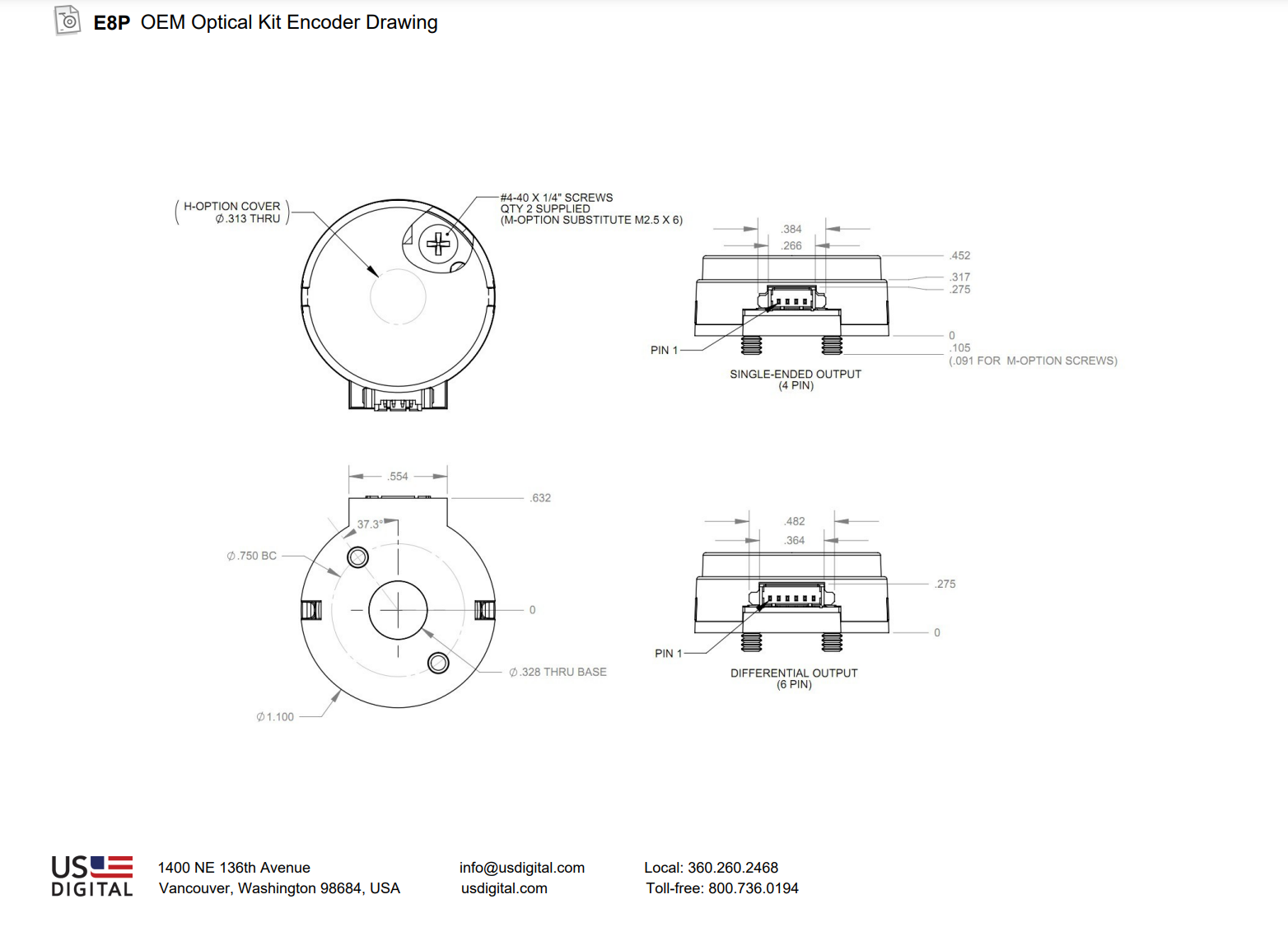

- Single-ended or differential output option

- A and B quadrature TTL outputs

- Fits shaft diameters from 0.118 in. (3mm) to 0.276 in. (7mm)

- Accepts +/- 0.020 in. axial shaft play

- Off-axis mounting tolerance of 0.010 in.

- Count frequency from DC to 30 kHz

- 180 to 512 cycles per rev (CPR)

- 720 to 2,048 quadrature states per rev.

- Single +5V supply

See more info below

Configure the E8P