Frequently Asked Questions

NOTE: There are many links in the FAQ to the Glossary, posts, or videos which provide a more comprehensive answer. If the answer to your question is not listed below, please contact our Technical Support team at 360-397-9999 or support@usdigital.com.

General

What is an encoder?

An encoder is an electro-mechanical device that translates physical motion into an electrical signal. That data can be used by a control system to determine speed, acceleration, direction, and/or position.

How do I choose an encoder?

The right encoder depends on many factors. We’ve created a white paper that will help you through the process. Things you will need to consider are:

Are you measuring rotary or linear motion?

Will the encoder mount onto an existing shaft or do you need an encoder that has a shaft built into it.

Do you need an encoder that can always report the exact position when powered up or do you only need it to report how much it is moving and the direction it is moving.

If you are choosing an incremental encoder, do you need an index?

Which resolution do you need? If choosing an incremental encoder, do you need a differential output?

Which encoder output is compatible with your data acquisition system?

What voltage encoder would work best for your system?

Is the encoder rated to be able to function properly at the maximum speed you anticipate using?

Is an IP rating required?

What bore sizes are available on the encoder kits?

For the available bore sizes, review the datasheet for the encoder you select. Use this comparison chart to see the bore size range for all our encoder kits.

What is the difference between an incremental and an absolute encoder?

Incremental encoders provide an output as to the movement of a shaft but upon power up, shaft angle position is unknown. But if the encoder has an index, position can be determined by performing a homing cycle. Absolute encoders report exact angle position upon power up with no movement required.

What is an index?

What is an index?

An index is a unique mark at one or more points on a disk or linear strip. The index enables an exact angle position to be known when the encoder detects that mark.

How do I clean an encoder disk?

The robust design of our encoders provides for consistent functioning even when a disk has small imperfections, scratches and specks on it. “Cleaning” a disk can cause more problems than it might fix. US Digital has a post and video addressing this topic in more detail.

What tolerances are held for bore size on the encoder kits?

This chart shows the tolerances for both bore size on encoder kits and shaft diameter on shafted encoders.

Resolution

What is encoder resolution?

What is encoder resolution?

Just like the different divisions a measuring tape (inches, ½ inch, ¼ inch etc.), the resolution on an encoder defines how coarse or fine of a measurement can be determined. The higher the resolution, typically called out in CPR, the more unique positions can be resolved in the rotation of an encoder.

What is the difference between encoder resolution, accuracy, and precision?

What is the difference between encoder resolution, accuracy, and precision?

Encoder resolution identifies the smallest measurement that can be made. Encoder accuracy is the term used to compare the target position with the actual position. Encoder precision refers to the repeatability—comparing the change in successive measurements.

What are the minimum and maximum resolutions available on US Digital incremental encoders?

For encoders using 1" diameter disks, CPR values range from 32 to 5000. Those are the resolutions available on the following encoders: E2, E5, S1, S5, H1, H5, HB5M)

For encoders using 2" diameter disks, CPR values go from 64 to 10000. Those resolutions are available on these encoders: E3, E6, S2, S6, H3, H6, HB6M, HD25 For linear strips LPI values range from 120 to 500 using the EM1 module and 1000 to 2000 using the EM2 encoder module.

E4T & S4T CPR values range from 100 to 1,000.

E8T CPR values go from 180 to 720

EC35 CPR values range from 500 to 60,000

E16 CPR values range from 250 to 4,096

M3K CPR ranges from 1 to 8,192 for Incremental and 12-bit PWM for Absolute

Which resolution do I need?

Which resolution do I need?

This is a calculation you need to perform based on the smallest increment you need to monitor for the application. For example, if your application is measured in degrees as on a rotary encoder, you will divide 360 degrees by the number or fractions of a degree you have determined you need to be able to measure (360/X). The result will be your minimum resolution. Having determined that, you will choose a resolution equal to or greater than that number. Keep in mind that depending on the capability of your data acquisition system, it may be able to take the CPR and measure up to four times that amount (PPR).

How can I change the resolution of my encoder?

It is technically possible to change the resolution of our kit encoders, however, doing so requires swapping out core components for new ones that support the desired resolution. Changing the disk alone will not change the resolution. For encoders that use our EM1 and EM2 modules, you’d need to buy a new HubDisk and module. For miniature encoders, you’d need to buy a new HubDisk and board. You may find it simpler and less expensive to buy a new encoder.

Mounting

How do I mount a linear encoder strip?

As each application is unique, we are unable to give definitive instructions on how to mount the linear strip. A common method we have seen is clamping the back portion of the linear strip between two solid surfaces, with just the required quadrature track exposed.

How critical is encoder alignment?

Each encoder has specifications on its datasheet giving the alignment tolerances. Not staying within those tolerances may cause anything from no output to an inconsistent one. We provide assembly tools with each encoder kit to ensure proper alignment.

Where can I find assembly instructions?

The assembly instructions for each encoder are located near the top on each encoder kit product page on the website, but they, along with accompanying videos, can be found on the Encoder Assembly Instructions Page.

Environmental

If an encoder is being installed in an electrically noisy environment, what can be done to mitigate the potential interference with the encoder signals?

If an encoder is being installed in an electrically noisy environment, what can be done to mitigate the potential interference with the encoder signals?

Using an encoder with a differential output and using a shielded cable will often mitigate signal distortion caused by an electrically noisy environment. Other steps that can be taken include ensuring proper grounding and using a Faraday shield.

Will US Digital encoders work in a vacuum environment?

Our encoders have not been tested in a vacuum. We believe our encoders should work fine in a low vacuum environment, but you will need to test them to determine if they will work in your application or not.

Will US Digital encoders work in a radioactive environment?

Our encoders have not been tested in a radioactive environment. We believe the encoders will perform just fine in this environment. Regardless you will need to test them to determine if they will work in your application or not.

Do US Digital encoders work well in a dusty environment?

Our encoders use an LED with a phased array detector. This essentially means that the sensor is not just focused on only one point of the disk but is looking simultaneously at multiple line and window pairs. That way, a flaw at one spot on the disk is easily averaged out. This robust design allows for a consistent signal output even when dust or other imperfections exist, such as those you would expect from everyday use and the handling of encoders. Furthermore, our LEDs operate in the infrared spectrum, which means they're less susceptible to physical obstructions than visible light.

Do US Digital encoders work in a humid environment?

Our encoders have been tested and verified to work in non-condensing humidity environments but are not designed to be used in a condensing humidity environment.

Does vibration affect the operation of US Digital encoders?

We provide a vibration and shock rating for each encoder. The encoders have been tested to that standard. Any vibration or shock exceeding those standards can negatively affect the output of the encoder.

Electrical

What is the maximum cable length I can use with my encoder?

As a general rule of thumb, our single-ended output encoders work for cables up to 10 feet in length assuming they are not in an electrically noisy environment. For applications longer than 10 feet, a differential output encoder and shielded cable is recommended. If you have questions about a specific application, please reach out to Technical Support.

What cable do I need for my encoder?

Once you configure an encoder on our website, you can find compatible products, cables and connectors listed near the bottom of the product page.

What is the difference between single-ended and differential outputs?

Single-ended is the most frequently used encoder output where commonly the output alternates between 0 and 5VDC. For an encoder with a differential output, for each channel that alternates between 0 and 5VDC, there is a complementary channel that at the same time, alternates between 0 and -5VDC. A differential signal allows for longer cable runs and can be used in electrically noisy environments.

What can cause erratic signals from my encoder?

The most common source of erratic signals from an encoder is misalignment. We provide alignment and spacer tools with our encoder kits to ensure consistent signal output. Electrical interference can also cause erratic signals.

What voltages can be used on US Digital encoders?

Most of our encoders require 5VDC power. However, some of our encoders operate on 12VDC power, and several of our encoders can operate on voltages from 7.5 to 30VDC.

How do I test my encoder?

The best tool for testing an encoder and being able to see the signal output is an oscilloscope. US Digital does have a QSB which when connected to a computer does have the ability to provide some information like encoder CPR, count, position and current speed.

Are encoders susceptible to ESD (electrostatic discharge)?

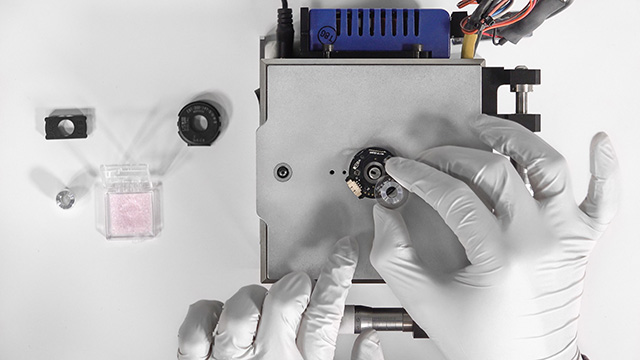

Some of the electronic components of encoders are susceptible to ESD which is why we recommend wearing a grounding strap when handling encoders and encoder components.

Jump to...