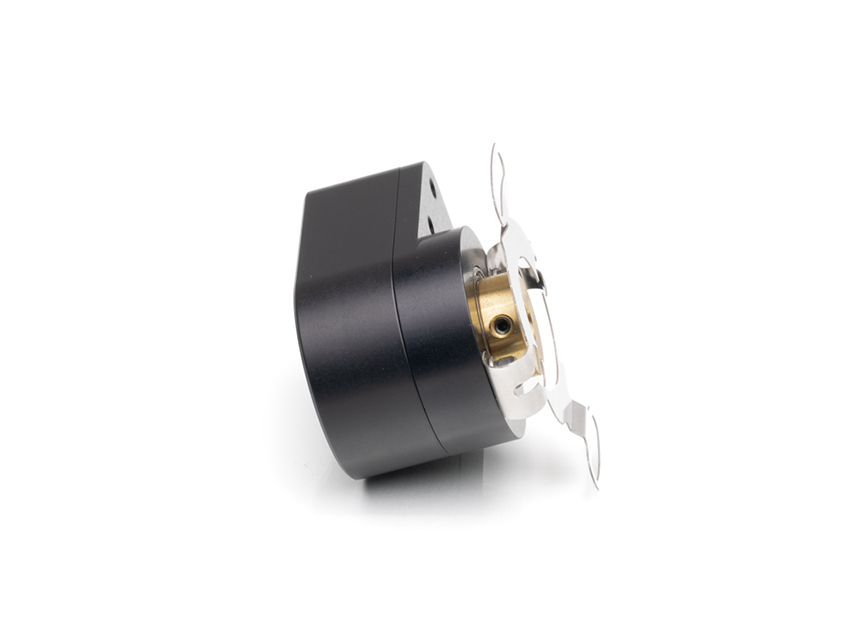

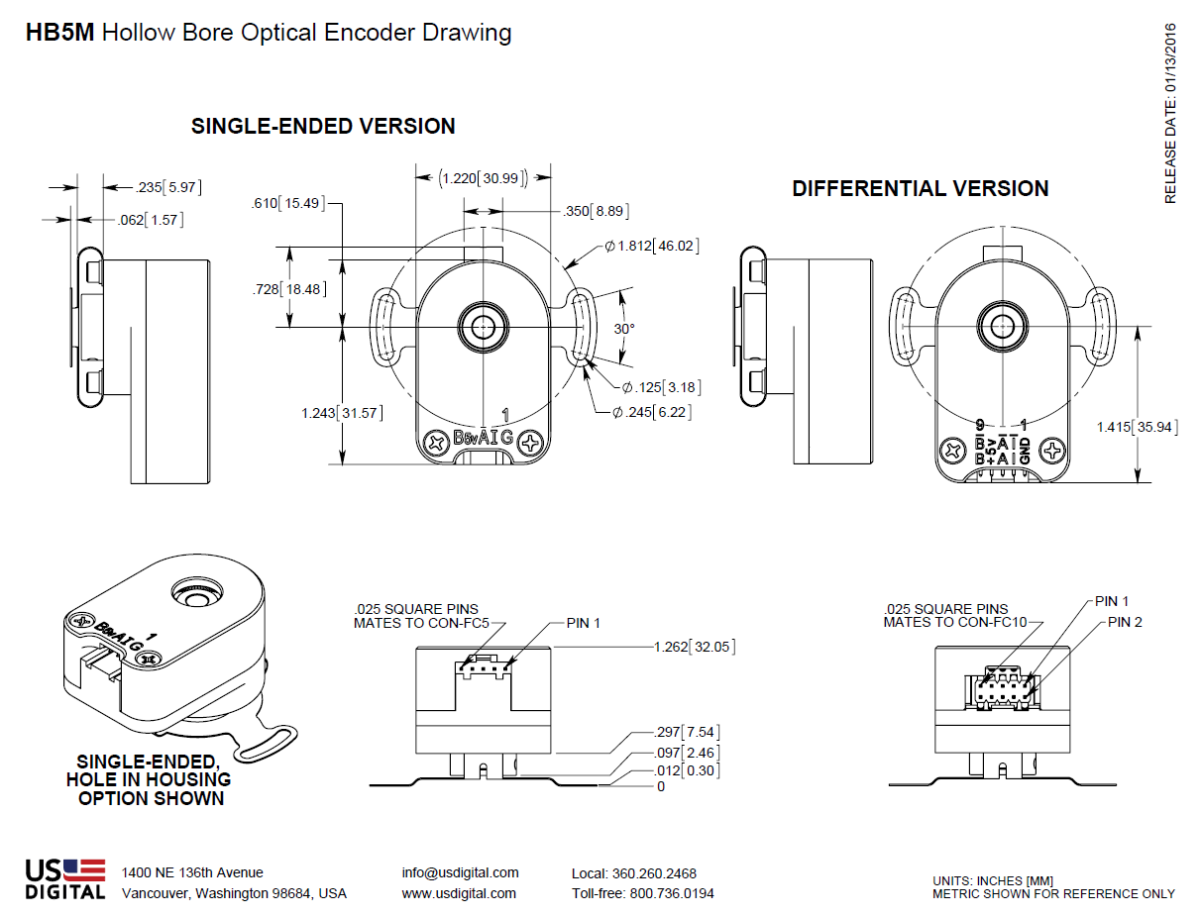

HB5M Hollow Bore Optical Encoder

HB5M Features

- Hollow bore (hollow shaft/thru-bore) bearing design

- Rugged anodized aluminum housing

- Heavy-duty ball bearings track up to 6,000 RPM

- Positive latching polarized connector

- 2-channel quadrature with optional index

- Multiple Output Drive Options

- 32 to 5,000 cycles per revolution (CPR)

- 128 to 20,000 pulses per revolution (PPR)

See more info below

Configure the HB5M